Category: Welding Application List

Welding Application List

Connector Laser Welding

Application Description

Auto parts such as cylinder gasket and others.

Standard

The welding point is smooth and color is symmetrical.

No damage or influence on the rest of the components during welding.

After the welding deformation of the product should be less than 5mm.

Advantage

Superior rate ≥99%

Welding speed: 70mm/s

Small deformation

Technology

Difficulties

1. The cylinder gasket is only 0.55mm need to achieve automatic uploading and unloading;

2. The cylinder gasket is round need to the fixture design does not affect the entire round of welding (without interruption);

3. Welding deformation control within 5mm.

Solution

Tips 1: Use suction tray and servo transmission mechanism to achieve the pick-and-place cylinder gasket, using double material inspection to confirm that the pick-up is a single piece;

Tips 2: Use circular heavy parts to press cylinder gasket, and other mechanisms are withdrawn during welding to allow the welding space;

Tips 3: Fixtures are clamped in the circular weld seam, at the meanwhile adjust welding technology parameter to reduce heat input.

Features

- The uploading reminder system, it will remind operator to upload product when finish welding;

- The control system not only can control the components of laser welding machine switch, laser output, protective air, but also functions of interlocking, alarm, and failure display;

- The control system has maintenance testing and self-diagnosis programs; it has the function of displaying the type of fault;

- Use four position turntable, automatic uploading and unloading, which can achieve high production efficiency and small work site;

- Double material inspection to detect accurate feeding;

- Use scanner for high speeding welding.

System Including

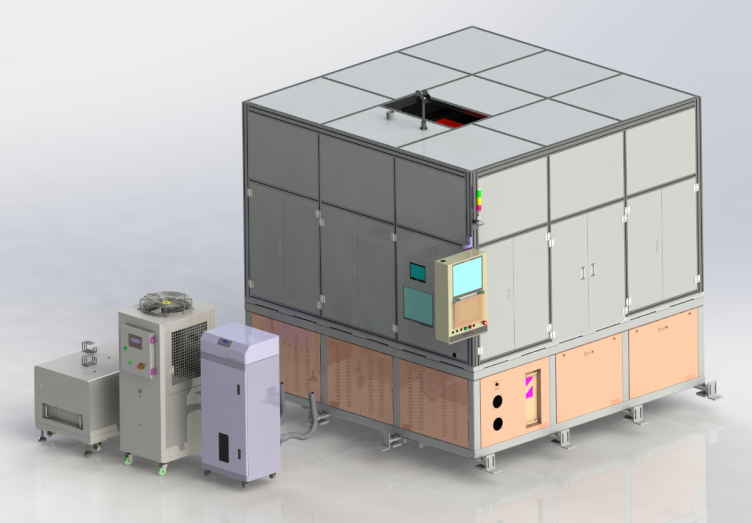

This cylinder gasket laser welding system includes laser welding machine, chiller, smoke purifier, workstation, scanner, protective room, monitor, etc.

Parameters

| Dimension | 4800(L)*3100(W)*2500(H)mm |

| Linear module positioning | 100-800mm |

| Repeat Accuracy(XYZ) | ±0.02mm |

| Productivity/Efficiency | 12S/PC |

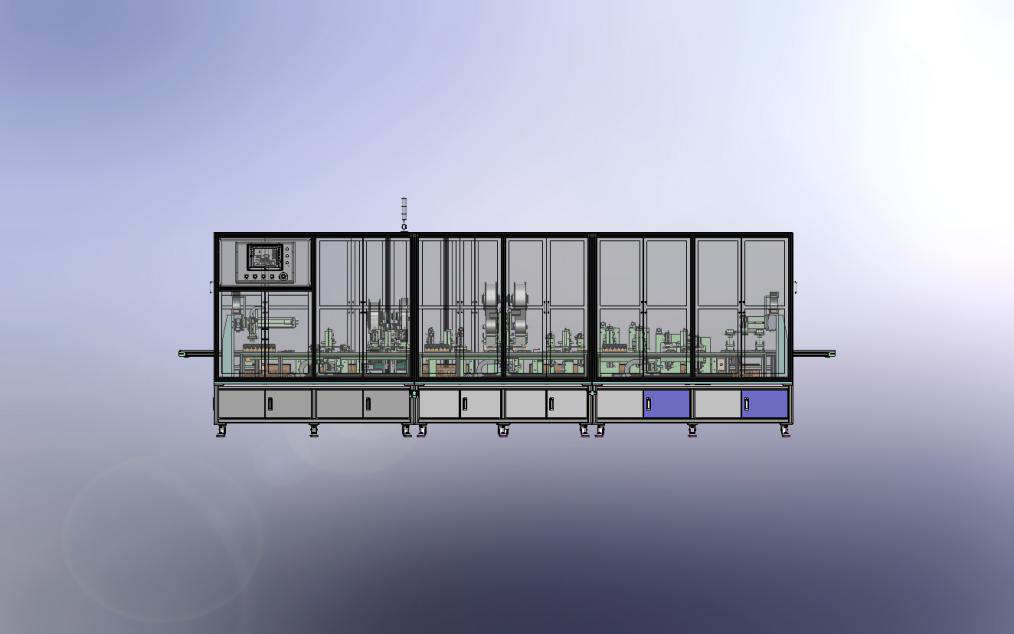

Battery Pole Ear Laser Welding

Application Description

Mobile Phone Battery Specification

Length: 40-120mm

Width: 30-80mm

Height: 2-5mm

Standard

The welding surface is smooth, and no obvious color change, no welding penetration.

Advantage

Superior rate ≥99 %

Productivity/Efficiency≥900 UPH

Welding speed 110~130mm/s

Technology

Difficulties

1. The pole ear is thin so that it is easy to deform and lead to poor welding.

2. The welding energy is unstable, and it is easy to produce welding penetration.

Solution

Tips 1: Integrate the laser welding machine with the position of pole ear shaping, cutting, dimension detection, and protection board welding avoid the risk of pole ear deformation.

Tips 2: Use energy negative feedback to ensure the stability of the energy.

Tips 3: Use the scanner to ensure the welding efficiency.

Features

- This battery pole ear laser welding system is used for scan code, internal resistance voltage test, pole ear shaping, pole ear cutting, protection plate welding, etc.;

- Flexible design is compatible with a wide range of product types;

- High degree of automation, the protection plate can be extended to automatically uploading;

- High welding speed, excellent effect and high superior rate;

- Key technology parameters (OCV test data, pole ear size, welding parameters, etc.) can be uploaded to the traceability system;

System Including

This battery pole ear laser welding system includes laser welding machine, worktable, chiller, etc.

Parameters

| Dimension | 3000(L)*1500(W)*1800(H)mm |

| Repeat Accuracy | ±0.03mm |

| Failure Rate | ≤2% |

| Productivity/Efficiency | 900 UPH |

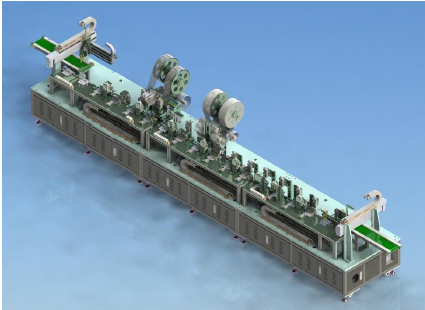

Battery Glue Pasting

Application Description

Mobile Phone Battery Specification

Length: 40-120mm

Width: 30-80mm

Height: 2-10mm

Standard

The effect of glue pasting is good, without wrinkles, bubbles, deviation or miss glue pasting.

Advantage

Superior rate ≥99%

Productivity/Efficiency≥900 UPH

Technology

Difficulties

1. There are various kinds of glue tapes, and the position of glue pasting varies according to the product and technology.

2. The glue pasting movement of mobile phone head is complicated, and it needs to be folded several times after pasting.

Solution

Tips 1: Use automatic stripping mechanism to complete the pasting operation, to achieve the tape of chip head and double-sided adhesive automatic glue;

Tips 2: Assist the bending mechanism to complete the automatic folding of the adhesive paper to ensure that the adhesive paper has good effect without wrinkles;

Tips 3: Allow online change glue and products types quickly to convenient for customers to make small production.

Features

- This battery glue pasting system is used for scan code, chip leveling, chip of glue pasting, wrap angle, FPC flexible connector bending, side way glue pasting, etc.;

- Flexible design is compatible with a wide range of product types;

- High working efficiency.

System Including

This battery glue pasting system including glue pasting workstation, etc.

Parameters

| Dimension | 5200(L)*900(W)*1700(H)m |

| Repeat Accuracy | ±0.03mm |

| Failure Rate | ≤2% |

| Productivity/Efficiency | 900UPH |

Auto Seat Frame Laser Welding

Application Description

Auto white body such as seat frame and others.

Standard

The surface of welding seam is smooth;

There is even pattern in the welding seam;

No air holes, spatter, burn-through, etc.

Advantage

Welding speed ≥70mm/s;

Flying welding with high efficiency, can jump in milliseconds between welding seam in the scanning range.

Technology

Difficulties

1. The laser welding needs smaller gap, and the product gap is difficult to ensure.

2. The robot needs to wait for manual uploading, so the productivity is no high.

3. The laser welding requires high level of safety, needs radiation protection, but the moving edge of the slide and turntable mechanism is difficult to protect.

Solution

Tips 1: Use intensive fixture design, add enough pressure blocks near the welding seam to eliminate the gap between products;

Tips 2: Use multiple welding position to improve overall productivity;

Tips 3: Use double shutter door to achieve double protection.

Features

- High welding quality;

- High reliability fixture clamping design to ensure the product gap;

- Optional welding quality monitoring system to monitor welding quality;

- Set 1-3 rotary table for different products welding;

- Multiple welding position for manual uploading and unloading, one robot for flying welding, which can reduce robot waiting time and improve efficiency.

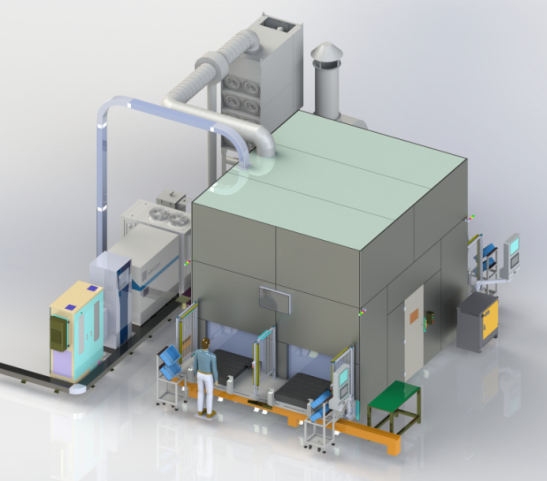

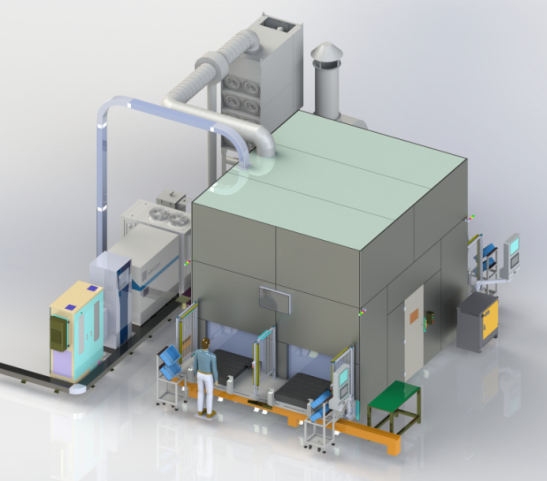

System Including

This auto seat frame laser welding system includes laser welding machine, laser head, chiller, smoke purifier, fixture, robot, electrical cabinet, shutter door, protective room, etc.

Parameters

| Dimension | 14(L)*4.5(W)*7(H)m |

| Welding speed | ≥70mm/s |

| Productivity/Efficiency | 35S/PC |

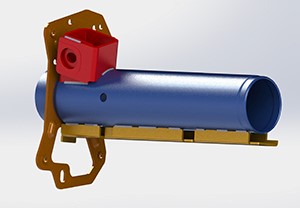

Auto Guiding Tube Bracket Laser Welding

Application Description

Auto parts such as auto guiding tube bracket and others.

Standard

The welding seam is smooth and color is symmetrical.

Depth of penetration reach 80% of plate.

Advantage

Superior rate ≥99.8%

Welding speed: 30mm/s

Technology

Difficulties

The fillet welding and requires the depth of penetration should reach 80% of plate;

There is anti-rust oil on the product surface, which is not good for welding.

Solution

Tips 1: When welding the angle of laser and the edge of product as close as possible at 20 degrees;

Tips 2: The fixture need to avoid interference with the product and the laser during fixture clamping;

Tips 3: Select appropriate incident angle, and constantly optimize technology parameter of laser power, welding speed, defocus amount, etc.;

Tips 4: Choose laser cleaning, it can remove surface oil oxides to get better welding quality.

Features

- The uploading reminder system, it will remind operator to upload product when finish welding;

- The control system not only can control the components of laser welding machine switch, laser output, protective air, but also functions of interlocking, alarm, and failure display;

- The control system has maintenance testing and self-diagnosis programs; it has the function of displaying the type of fault;

- Using four slide uploading position, the robot takes the laser head welding between four positions to improve productivity;

- Using welding quality monitoring LWM system to ensure welding quality.

System Including

This auto guiding tube bracket laser welding system includes laser welding machine, robot, workstation, chiller, LWM system, robot, smoke purifier, protection room, etc.

Parameters

| Dimension | 5000(L)*4000(W)*6000(H)mm |

| Linear module positioning (Y) | 1000mm |

| Air volume of smoke purifier | 8000m³/h |

| Repeat Accuracy(XYZ) | ±0.03mm |

| Productivity/Efficiency | 14S/PC |

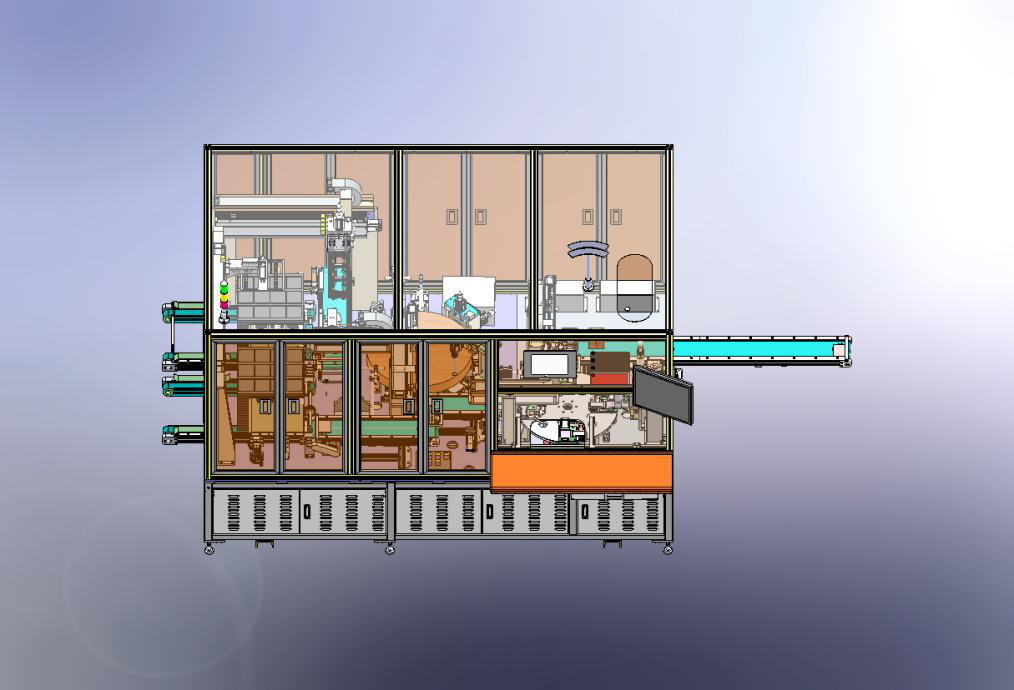

10PPM Square Battery Module Laser Welding

Application Description

Battery Module Specification

Length: 500mm

Width: 200mm

Height: 300mm

Advantage

Superior rate ≥99.8 %

Productivity/Efficiency≥10PPM

Technology

Welding battery module shell with traditional technology CMT, the welding speed is slow, the welding quality is poor, and the welding temperature has a great influence on battery. However, use laser welding machine + scanner can effectively solve the above problems.

Features

- This 10PPM Square Battery Module production line is used for battery module scan code, OCV test, thickness test, glue stacking, polarity detection, shell laser welding, weld seam test, insulation and voltage test, marking, gluing, curing, laser cleaning, Busbar welding, DCRI test, etc.;

- High degree of automation;

- Strong compatibility, different combinations of the same chip can be produced automatically;

- The production line tracing data synchronization with MES system.

System Including

This 10PPM square battery module laser welding system includes data tracking system, electrical performance test system, gluing system, battery shell welding system, after- welding test system, glue curing system, laser clean system, Busbar welding system, uploading and unloading system, etc.

Parameters

| Dimension | 46(L)*9(W)*3.5(H)m |

| Activation | ≧98% |

| Failure Rate | ≤2% |

| Productivity/Efficiency | 10PPM |