Deburring Machines

Product Categories

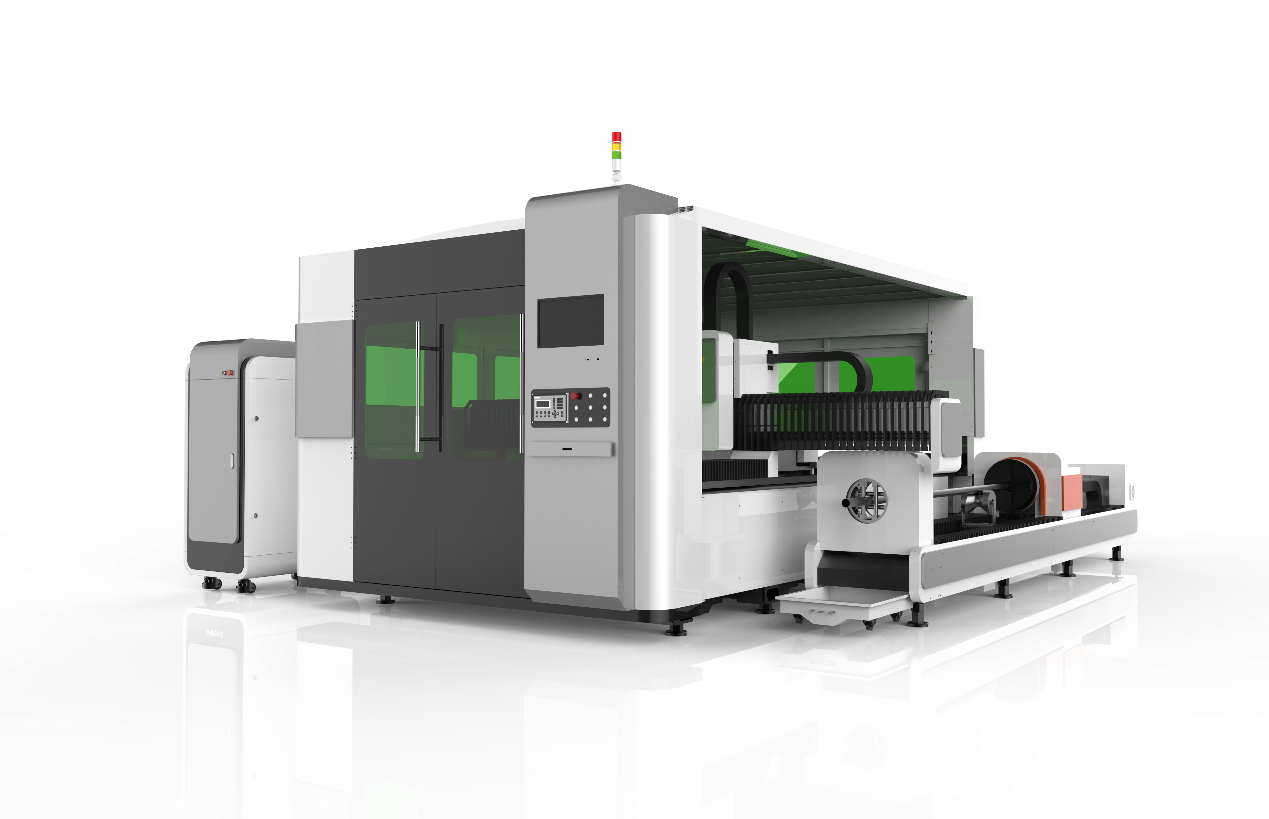

The model GZ1530EL1 fiber laser cutting machine is designed for both tube and plates cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

It has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, metal artwork, etc.; processing material like Stainless steel, carbon steel, Silicon steel, alloy steel, spring steel, copper, aluminum sheet, Zinc alloyed sheet, etc.

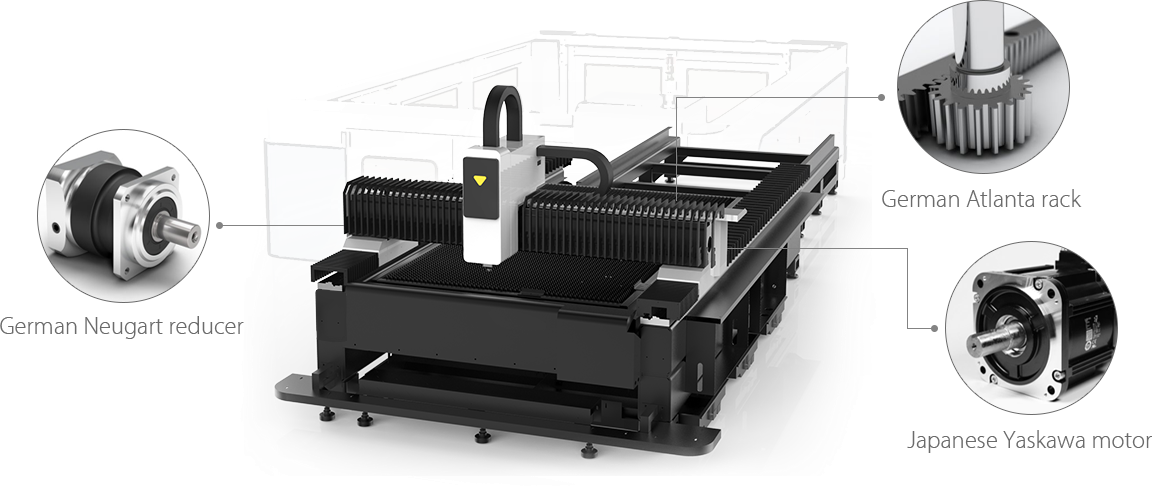

Transmission and Precision

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

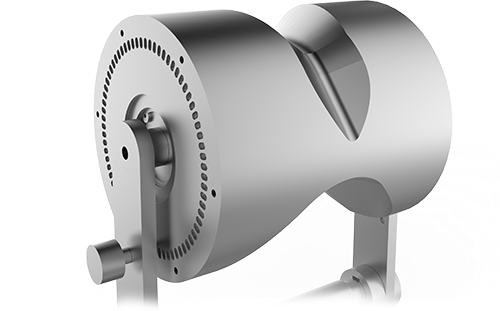

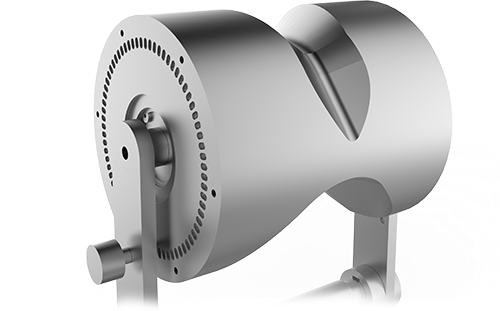

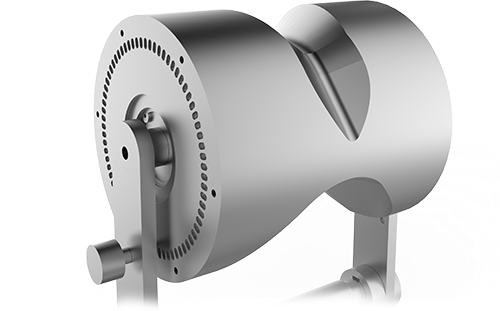

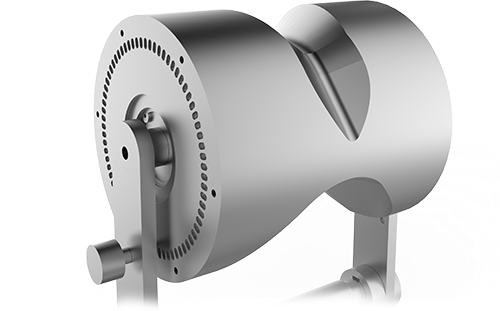

Auto Focus Cutting Head

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

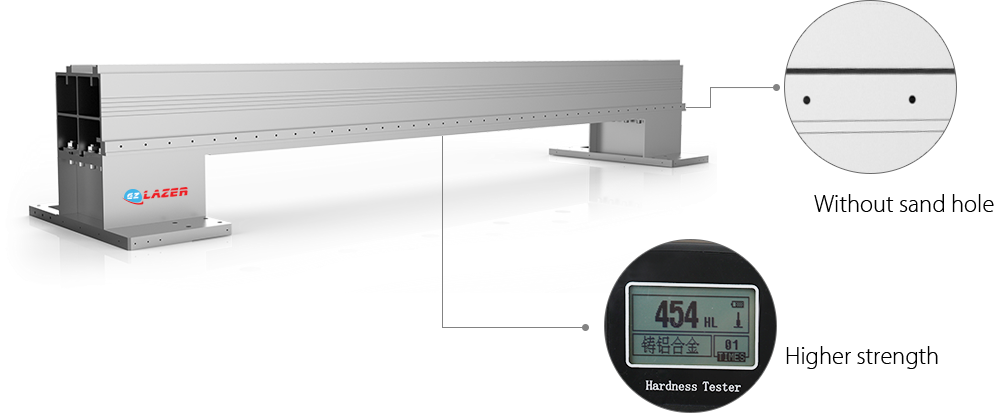

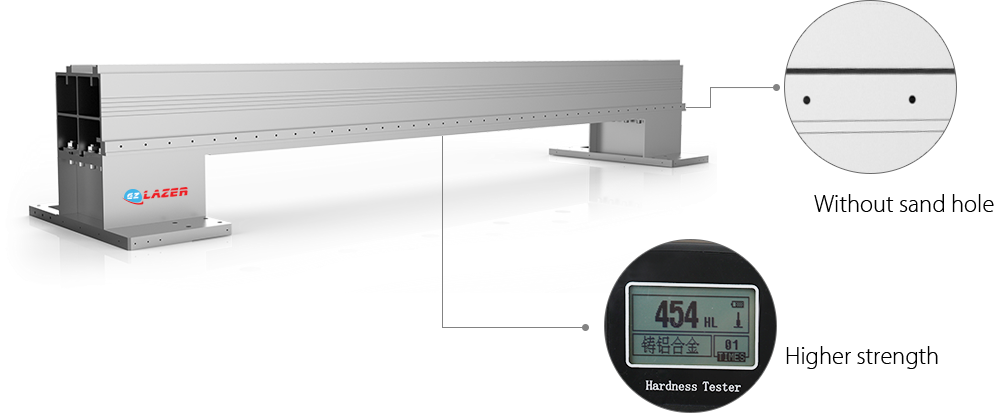

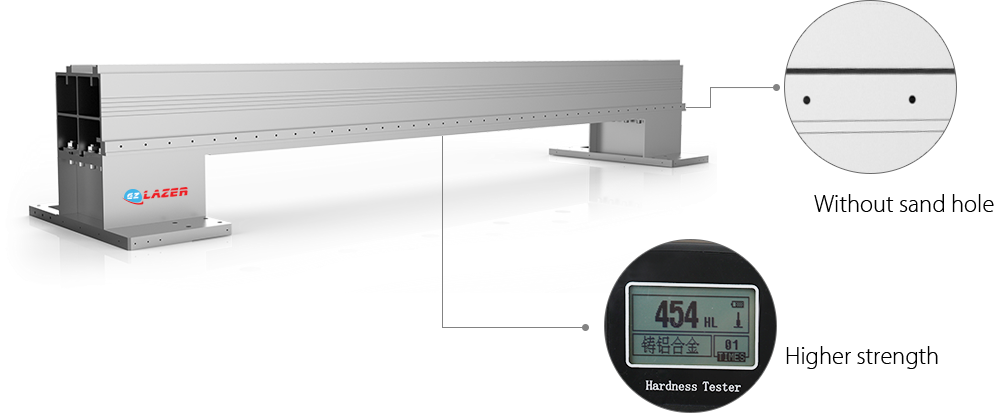

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Independent Control Cabinet

All electrical components and laser source are built-into the independent control cabinet with a dust -proof design to prolong the lifespan of the electrical components.

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

IPAD Designed Screen

IPAD designed screen, has a vertical screen display, different from the traditional horizontal screen display, which is with good response speed, higher contrast, wider view, low power consumption as well as high resolution. In addition, it possesses high brightness levels and lower reflectivity as well as solid glass panel sturdiness and durability.

| Laser Generator | Imported/Chinese fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000W/4000W |

| Working area | 1500*3000mm/1500*4000mm/2000*4000mm/2000*6000mm |

| Max. speed | 0-20m/min(Depending on the material and thickness) |

| Repeat positioning accuracy | ±0.02mm |

| X-axis travel | 1525mm(take 1500mm for example) |

| Y-axis travel | 3025mm(take 3000mm for example) |

| Z-axis travel | 100mm |

| Acceleration | 1.5G |

| Rotary device | 3m/6m, tube diameter 20~220mm |

| Transmission | High precision gear with double driving rack |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 5500KGs |

The model GZ1530CG1 fiber laser cutting machine is designed for both tube and plates cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

It has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, metal artwork, etc.; processing material like Stainless steel, carbon steel, Silicon steel, alloy steel, spring steel, copper, aluminum sheet, Zinc alloyed sheet, etc.

Transmission and Precision

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Auto Focus Cutting Head

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

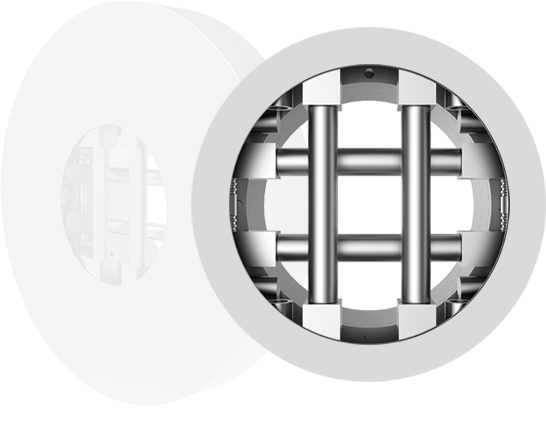

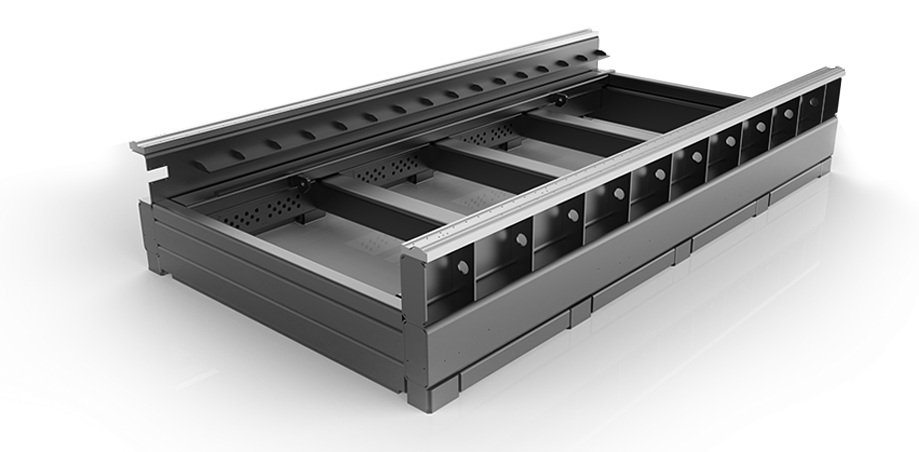

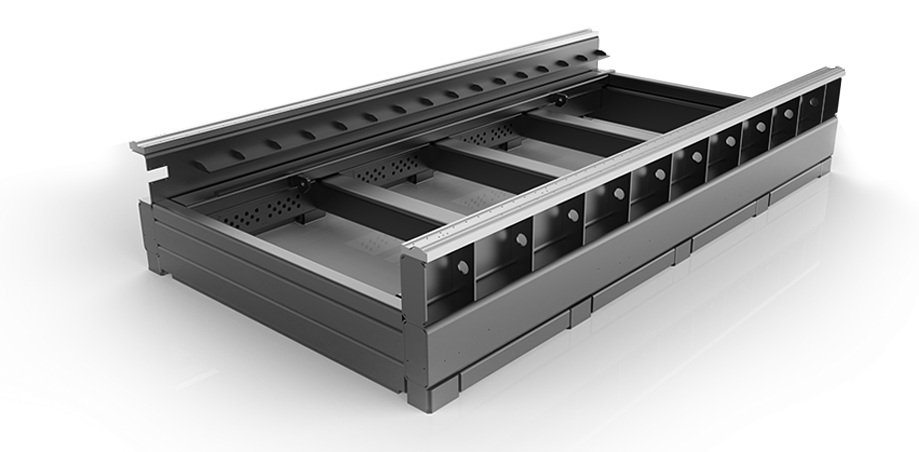

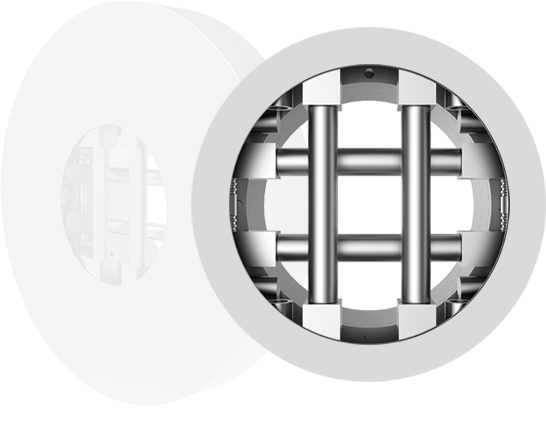

The Segmented Rectangular Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, and it also increases the resistance and stability of the guide rail to effectively avoid the deformation of the bed.

Independent Control Cabinet

All electrical components and laser source are built-into the independent control cabinet with a dust -proof design to prolong the lifespan of the electrical components.

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

| Laser Generator | Imported/Chinese fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000W/4000W |

| Working area | 1500*3000mm/1500*4000mm/2000*4000mm/2000*6000mm |

| Max. speed | 0-20m/min(Depending on the material and thickness) |

| Repeat positioning accuracy | ±0.02mm |

| X-axis travel | 1525mm(take 1500mm for example) |

| Y-axis travel | 3025mm(take 3000mm for example) |

| Z-axis travel | 100mm |

| Acceleration | 1.5G |

| Rotary device | 3m/6m, tube diameter 20~200mm |

| Transmission | Germany high precision gear with double driving rack |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 7500KGs |

The model GZ1530C1 fiber laser cutting machine is designed for both tube and plates cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

It has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, metal artwork, etc.; processing material like Stainless steel, carbon steel, Silicon steel, alloy steel, spring steel, copper, aluminum sheet, Zinc alloyed sheet, etc.

Transmission and Precision

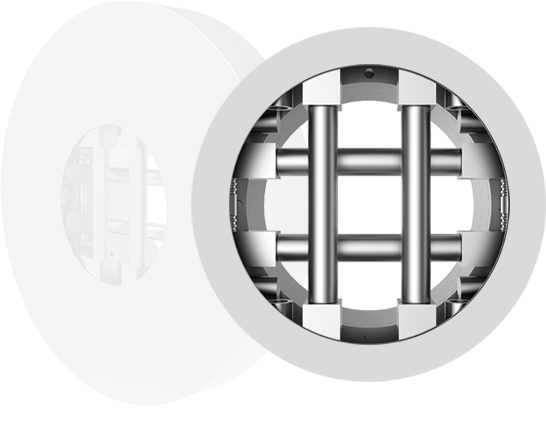

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Auto Focus Cutting Head

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

The Segmented Rectangular Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, and it also increases the resistance and stability of the guide rail to effectively avoid the deformation of the bed.

Independent Control Cabinet

All electrical components and laser source are built-into the independent control cabinet with a dust -proof design to prolong the lifespan of the electrical components.

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

| Laser Generator | Imported/Chinese fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000W/4000W |

| Working area | 1500*3000mm/1500*4000mm/2000*4000mm/2000*6000mm |

| Max. speed | 0-20m/min(Depending on the material and thickness) |

| Repeat positioning accuracy | ±0.02mm |

| X-axis travel | 1525mm(take 1500mm for example) |

| Y-axis travel | 3025mm(take 3000mm for example) |

| Z-axis travel | 100mm |

| Acceleration | 1.5G |

| Rotary device | 3m/6m, tube diameter 20~200mm |

| Transmission | Germany high precision gear with double driving rack |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 5500KGs |

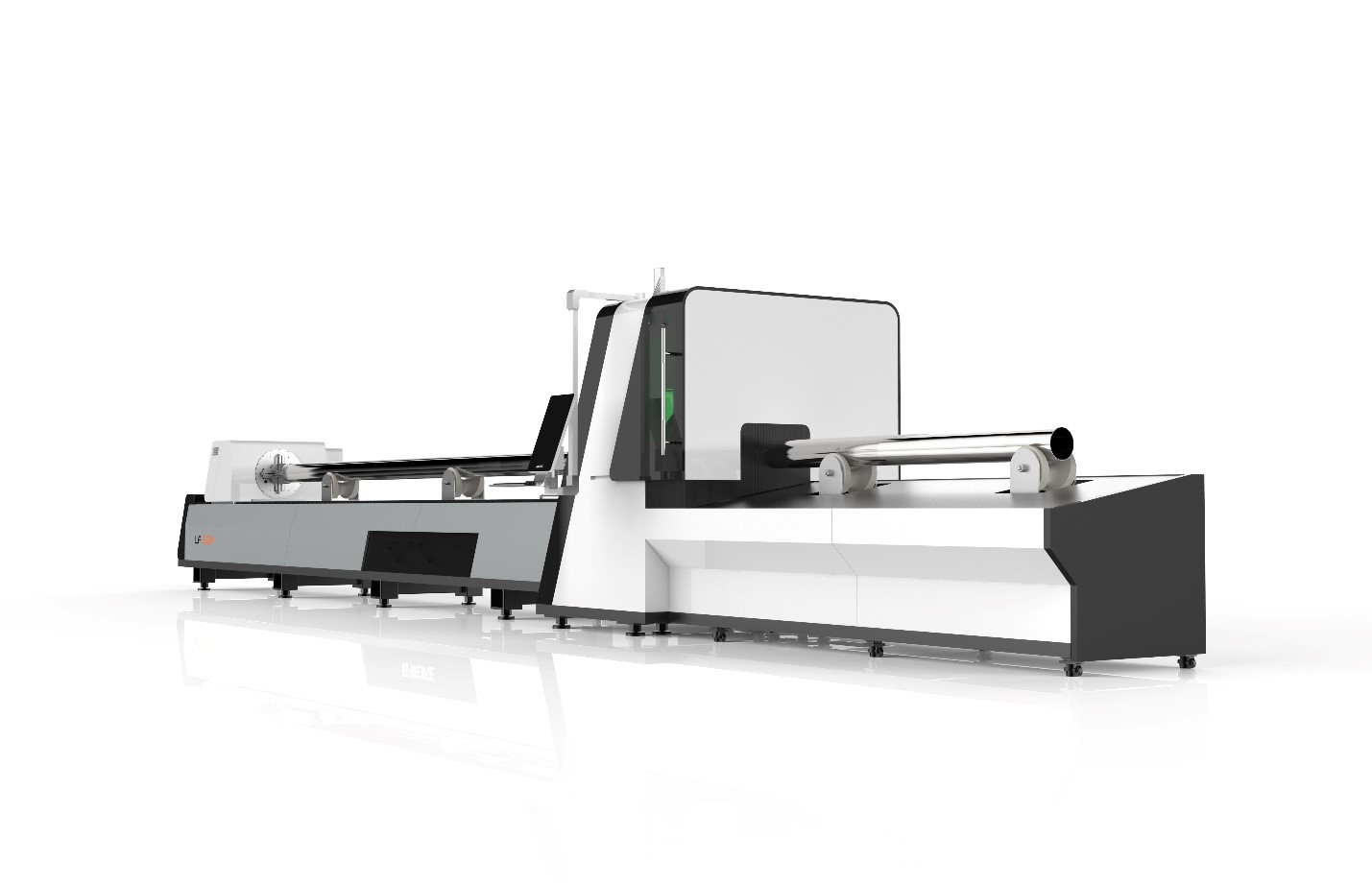

The model GZ60T2 fiber laser cutting machine is professionally designed for both round and square tube cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. It has been widely used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube. It can achieve the tubes/pipes multi-angle precision processing to fulfil the requirements.

Transmission and Precision

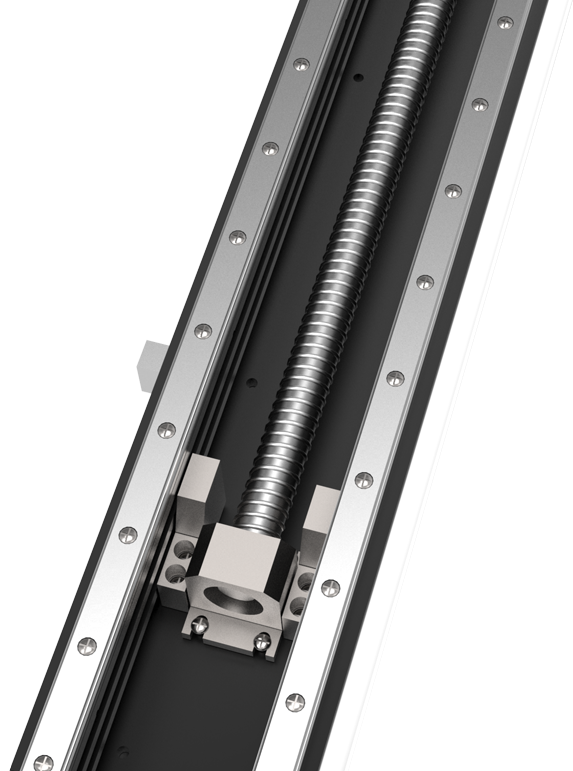

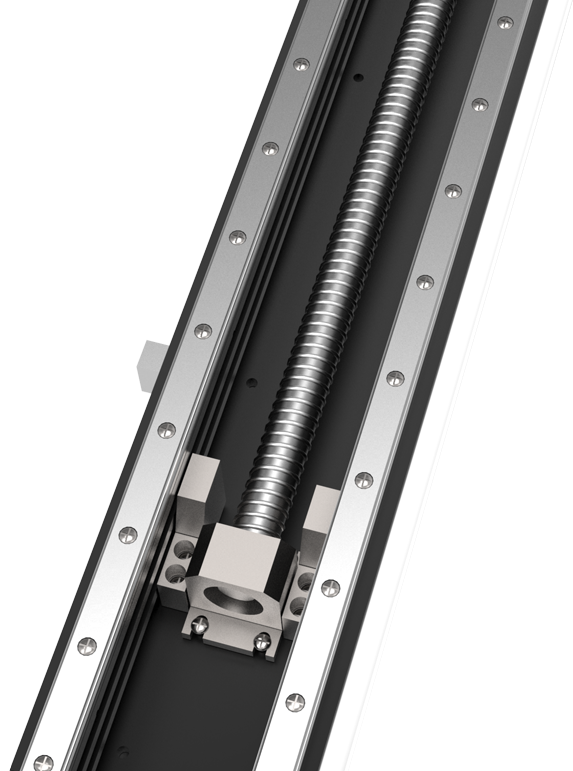

Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

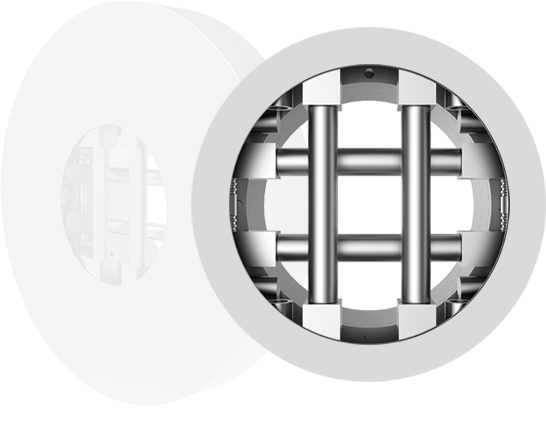

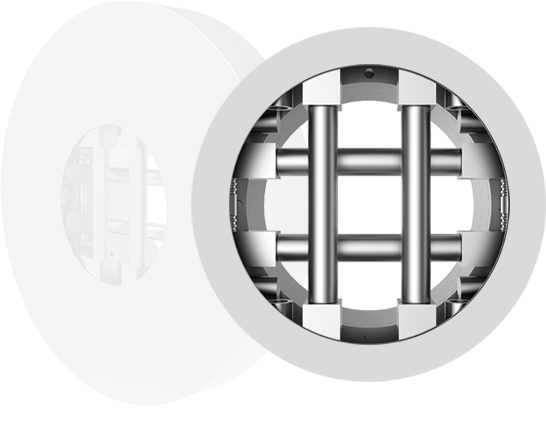

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Easy to Operate

It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation.

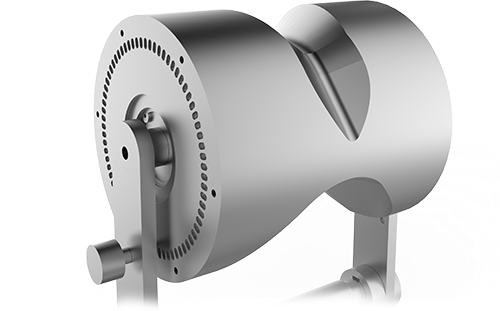

Auto Focus Cutting Head

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

| Model Type | GZ60T2-1000W / 1500W / 2000W |

| Laser Generator | Raycus/IPG fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000w/4000W |

| Repeat positioning accuracy | ±0.02mm |

| Tube device | 6m, tube diameter 20~220mm |

| Transmission | Taiwan TBI grinding screw drive |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 4500KGs |

The model GZ60T1 fiber laser cutting machine is professionally designed for both round and square tube cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. It has been widely used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube. It can achieve the tubes/pipes multi-angle precision processing to fulfil the requirements.

Transmission and Precision

Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Easy to Operate

It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation.

Auto Focus Cutting Head

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

| Model Type | GZ60T1-1000W / 1500W / 2000W |

| Laser Generator | Raycus/IPG fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000w/4000W |

| Repeat positioning accuracy | ±0.02mm |

| Tube device | 6m, tube diameter 20~220mm |

| Transmission | Taiwan TBI grinding screw drive |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 4500KGs |

This machine is designed compactly in small size. It adopts high speed scan-head and sealed CO2 laser tube, and uses high quality stable power supply. It has many advantages, such as high accuracy, quick speed, stable performance, and it can be used for marking and hole punching for all kinds of cloth materials, leathers and other materials. This machine owns the best quality with the most favorable price.

| Model | GZ80 |

| Laser power | 80W |

| Laser wave-length (um) | 10.64μm |

| Laser repetition frequency | ≤25kHz |

| Working area | 110*110mm, 200mmX200mm, 300mmX300mm |

| Marking depth (mm) | ≤3mm |

| Marking speed (mm) | ≤7000mm/s |

| Min. line width (mm) | 0.2mm |

| Min. character size (mm) | 0.5mm |

| Repetition accuracy (mm) | ±0.01 |

| Power consumed (kW) | <1200W |

| Electrical source | 220V 50Hz 8A |

| Cooling system | Water cooling |

| Software | Win XP + EZCAD marker system |

| Operating temperature | 0℃—30℃ |

| Net Weight | 200KGs |

| Working voltage | AC 110 – 220V±10%, 50 – 60Hz |

Wood, paper, leather, cloth, plexiglass, epoxy, acrylic, unsaturated polyester resin, wood products, fabric, leather, organic glass, epoxy resin and other non metal material

Widely used in leather, food, beverage, cloth, electronic, meter, communication instruments, arts and crafts, furniture, leather and costume, advertising label, model making, food packaging, electronic components, medicine packaging, printing plate making, shell label, etc. It can be combined with streamline for online marking.

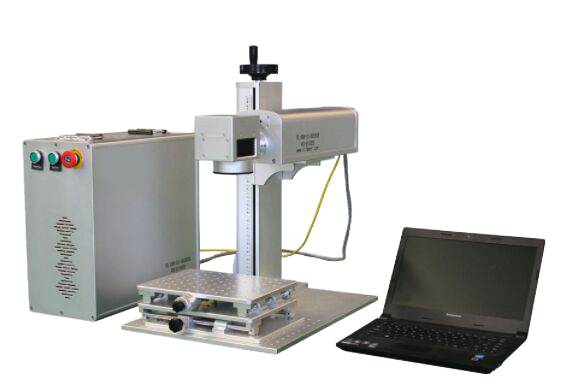

This series use imported high-speed scanning galvanometer from Germany with photoelectric conversion efficiency, fiber laser, long lifespan, high marking speed, high quality output beam and high reliability.

It is used in metals, and some nonmetal, such as gold, silver, iron, components of automobiles and motorcycle, packaging of goods, drink and cigarette, nameplate, jewelry, watches etc. It can make kinds of graphs, words and signals. It can be integrated in the industrial production process.

It’s very convenient to modify serial No. or date, even that it can act automatically including marking the current year, month, day, hour, minute and second. During the continuous working process, it timely tracks and modifies these data. Its characteristic is high marking speed and precision marking effect.

| Model | GZ50F3 |

| Laser Type | Ytterbium Fiber |

| Laser power | 50w(optional 30W, 20W) |

| Laser wave-length (nm) | 1060~1070nm |

| Q frequency | 20~100KHz |

| Working area | 110*110mm, 200mmX200mm, 300mmX300mm |

| Marking depth (mm) | ≤0.5mm |

| Min. line width (mm) | 0.015mm |

| Min. character size (mm) | 0.1mm |

| Max marking speed | ≤10000mm/s |

| Engraving line speed | ≤7000mm/s |

| Repetition accuracy (mm) | ±0.001mm |

| Beam quality m2 | 1.2~1.8m2 |

| Power consumed (kW) | <0.5kw |

| Electrical source | 220V 50Hz |

| Cooling system | Air cooling |

| Software | Win XP + EZCAD marker system |

| Graphic format supported | BMP,JPG,GIF,TGA, PNG,TIF,AI,DXF,DST,PLT |

| Operating temperature | 0℃—35℃ |

| Net Weight | 120KGs |

| Working voltage | AC 110 – 220V±10%, 50 – 60Hz |

Carve metal and nonmetal materials: common metal and alloy (all metals include iron, copper, aluminum, magnesium and zinc), rare metal and alloy (gold, nickel, and titanium), metal oxide, special surface process (phosphating, aluminum anodizing and electroplated surface), ABS material (electric apparatus shell, daily necessities), ink (light-transmitting keys, printing products), epoxy resin (packages and insulating layer of electronic components), mobile phone keypad, plastic translucent keys, electronic components, integrated circuits (IC), electrical appliances, communication products, sanitary ware, tools, accessories, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils and so on.

It is more suitable for circumstances that require super fine and high precision. It is applied to electronic components, integrated circuit (IC), electric apparatus, mobile communication, hardware products, tool fittings, precision instrument, glasses, watch and clock, jewelry, automobile parts, plastic keys, construction materials, PVC pipes, medical instruments, etc.

This series use imported high-speed scanning galvanometer from Germany with photoelectric conversion efficiency, fiber laser, long lifespan, high marking speed, high quality output beam and high reliability.

It is used in metals, and some nonmetal, such as gold, silver, iron, components of automobiles and motorcycle, packaging of goods, drink and cigarette, nameplate, jewelry, watches etc. It can make kinds of graphs, words and signals. It can be integrated in the industrial production process.

It’s very convenient to modify serial No. or date, even that it can act automatically including marking the current year, month, day, hour, minute and second. During the continuous working process, it timely tracks and modifies these data. Its characteristic is high marking speed and precision marking effect.

| Model | GZ50F2 |

| Laser Type | Ytterbium Fiber |

| Laser power | 50w(optional 30W, 20W) |

| Laser wave-length (nm) | 1060~1070nm |

| Q frequency | 20~100KHz |

| Working area | 110*110mm, 200mmX200mm, 300mmX300mm |

| Marking depth (mm) | ≤0.5mm |

| Min. line width (mm) | 0.015mm |

| Min. character size (mm) | 0.1mm |

| Max marking speed | ≤10000mm/s |

| Engraving line speed | ≤7000mm/s |

| Repetition accuracy (mm) | ±0.001mm |

| Beam quality m2 | 1.2~1.8m2 |

| Power consumed (kW) | <0.5kw |

| Electrical source | 220V 50Hz |

| Cooling system | Air cooling |

| Software | Win XP + EZCAD marker system |

| Graphic format supported | BMP,JPG,GIF,TGA, PNG,TIF,AI,DXF,DST,PLT |

| Operating temperature | 0℃—35℃ |

| Net Weight | 120KGs |

| Working voltage | AC 110 – 220V±10%, 50 – 60Hz |

Carve metal and nonmetal materials: common metal and alloy (all metals include iron, copper, aluminum, magnesium and zinc), rare metal and alloy (gold, nickel, and titanium), metal oxide, special surface process (phosphating, aluminum anodizing and electroplated surface), ABS material (electric apparatus shell, daily necessities), ink (light-transmitting keys, printing products), epoxy resin (packages and insulating layer of electronic components), mobile phone keypad, plastic translucent keys, electronic components, integrated circuits (IC), electrical appliances, communication products, sanitary ware, tools, accessories, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils and so on.

It is more suitable for circumstances that require super fine and high precision. It is applied to electronic components, integrated circuit (IC), electric apparatus, mobile communication, hardware products, tool fittings, precision instrument, glasses, watch and clock, jewelry, automobile parts, plastic keys, construction materials, PVC pipes, medical instruments, etc.

This series use imported high-speed scanning galvanometer from Germany with photoelectric conversion efficiency, fiber laser, long lifespan, high marking speed, high quality output beam and high reliability.

It is used in metals, and some nonmetal, such as gold, silver, iron, components of automobiles and motorcycle, packaging of goods, drink and cigarette, nameplate, jewelry, watches etc. It can make kinds of graphs, words and signals. It can be integrated in the industrial production process.

It’s very convenient to modify serial No. or date, even that it can act automatically including marking the current year, month, day, hour, minute and second. During the continuous working process, it timely tracks and modifies these data. Its characteristic is high marking speed and precision marking effect.

| Model | GZ50F1 |

| Laser Type | Ytterbium Fiber |

| Laser power | 50w(optional 30W, 20W) |

| Laser wave-length (nm) | 1060~1070nm |

| Q frequency | 20~100KHz |

| Working area | 110*110mm, 200mmX200mm, 300mmX300mm |

| Marking depth (mm) | ≤0.5mm |

| Min. line width (mm) | 0.015mm |

| Min. character size (mm) | 0.1mm |

| Max marking speed | ≤10000mm/s |

| Engraving line speed | ≤7000mm/s |

| Repetition accuracy (mm) | ±0.001mm |

| Beam quality m2 | 1.2~1.8m2 |

| Power consumed (kW) | <0.5kw |

| Electrical source | 220V 50Hz |

| Cooling system | Air cooling |

| Software | Win XP + EZCAD marker system |

| Graphic format supported | BMP,JPG,GIF,TGA, PNG,TIF,AI,DXF,DST,PLT |

| Operating temperature | 0℃—35℃ |

| Net Weight | 120KGs |

| Working voltage | AC 110 – 220V±10%, 50 – 60Hz |

Carve metal and nonmetal materials: common metal and alloy (all metals include iron, copper, aluminum, magnesium and zinc), rare metal and alloy (gold, nickel, and titanium), metal oxide, special surface process (phosphating, aluminum anodizing and electroplated surface), ABS material (electric apparatus shell, daily necessities), ink (light-transmitting keys, printing products), epoxy resin (packages and insulating layer of electronic components), mobile phone keypad, plastic translucent keys, electronic components, integrated circuits (IC), electrical appliances, communication products, sanitary ware, tools, accessories, knives, eyeglasses and clocks, jewelry, auto parts, luggage buckle, cooking utensils and so on.

It is more suitable for circumstances that require super fine and high precision. It is applied to electronic components, integrated circuit (IC), electric apparatus, mobile communication, hardware products, tool fittings, precision instrument, glasses, watch and clock, jewelry, automobile parts, plastic keys, construction materials, PVC pipes, medical instruments, etc.