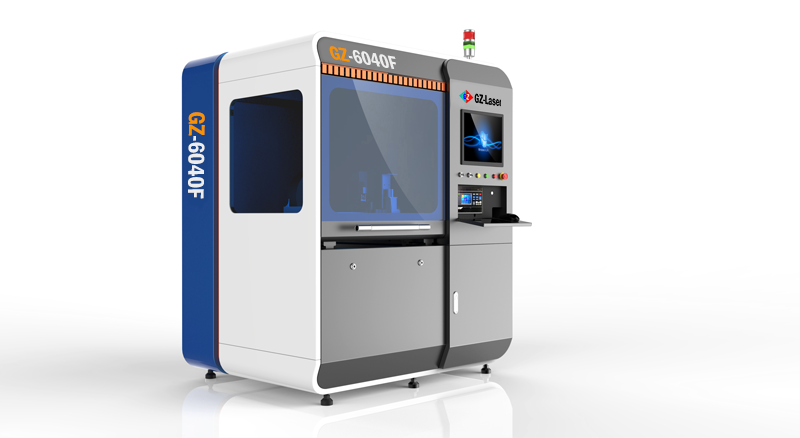

GZ6040F

Product Introduction

The model GZ6040F high precision fiber laser cutting machine uses imported Japan AC servo drive motor drive system. The adopted machine kinematics grinding grade screw driver and linear guide rails guarantee high-speed equipment, high-precision, high reliability.

It has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, metal artwork, etc.; processing material like Stainless steel, carbon steel, Silicon steel, alloy steel, spring steel, copper, aluminum sheet, Zinc alloyed sheet, etc., which requires very high precision finishing.

Main Configuration

Transmission and Precision

- High precision TBI grinding ball screw transmission, double drive for Y axis

- Panasonic AC servo motor and drive from Japan

- High precision HIWIN guide rail from Taiwan

- High Precision TBI grinding ball screw transmission for X and Z axis

- Schneider Electric Relays

- Professional Cypcut control system

Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

- Auto Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

- Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

- Long Life Span

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

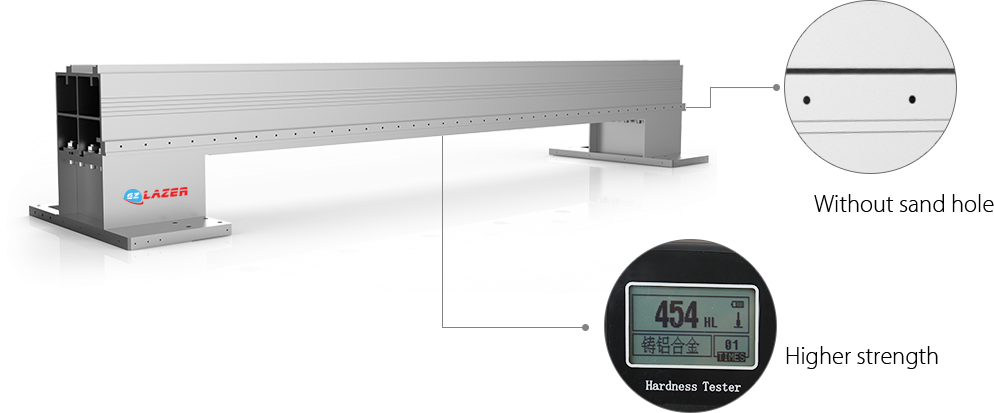

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Safety and No Pollution

- With a fully enclosed design.

- The observation window adopts European CE standard laser protective glass.

- The smoke produced by cutting can be filtrated inside, it’s non-polluting and environment friendly.

Technical Parameters

| Laser Generator | Imported/Chinese fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000W |

| Working area | 900*600mm |

| Max. speed | 0-20m/min(Depending on the material and thickness) |

| Repeat positioning accuracy | ±0.008mm |

| X-axis travel | 900mm |

| Y-axis travel | 600mm |

| Acceleration | 0.5G |

| Transmission | Grinding precision screw drive |

| Power supply | 220V/50Hz~60Hz |

| Gross weight | 800KGs |

Fiber Laser Cutting Machine Features

- Widely used in glasses, electronics, appliances and other precision machinery, hardware, microelectronics industry

- 600 °c heat treatment and 24 hours with the furnace cooling, 8 meters gantry milling finishing, precision welding protection of carbon dioxide, to ensure the normal use for 20 years without deformation

- Rail installation with precision collimator test, the accuracy reaches 0.008mm

- Taiwan grinding screw drive.

- High precision, speed, cutting surface smooth

- Configure Panasonic servo system inertia in driving high accuracy

- Fully enclosed protective cover

- Dual Rail and Dual Driver Design

- Dual Rail and Dual Driver Design