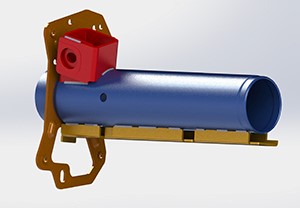

Auto Guiding Tube Bracket Laser Welding

Application Description

Auto parts such as auto guiding tube bracket and others.

Standard

The welding seam is smooth and color is symmetrical.

Depth of penetration reach 80% of plate.

Advantage

Superior rate ≥99.8%

Welding speed: 30mm/s

Technology

Difficulties

The fillet welding and requires the depth of penetration should reach 80% of plate;

There is anti-rust oil on the product surface, which is not good for welding.

Solution

Tips 1: When welding the angle of laser and the edge of product as close as possible at 20 degrees;

Tips 2: The fixture need to avoid interference with the product and the laser during fixture clamping;

Tips 3: Select appropriate incident angle, and constantly optimize technology parameter of laser power, welding speed, defocus amount, etc.;

Tips 4: Choose laser cleaning, it can remove surface oil oxides to get better welding quality.

Features

- The uploading reminder system, it will remind operator to upload product when finish welding;

- The control system not only can control the components of laser welding machine switch, laser output, protective air, but also functions of interlocking, alarm, and failure display;

- The control system has maintenance testing and self-diagnosis programs; it has the function of displaying the type of fault;

- Using four slide uploading position, the robot takes the laser head welding between four positions to improve productivity;

- Using welding quality monitoring LWM system to ensure welding quality.

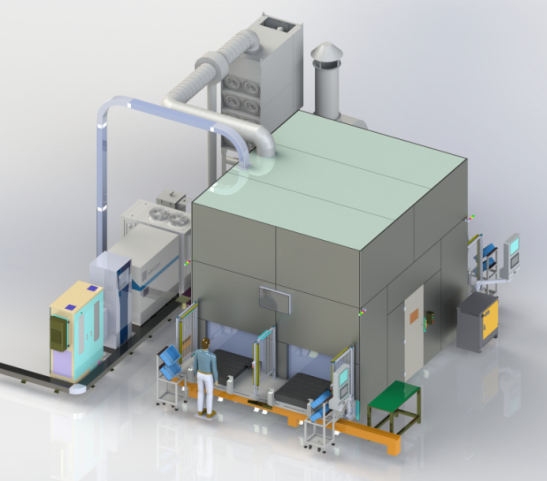

System Including

This auto guiding tube bracket laser welding system includes laser welding machine, robot, workstation, chiller, LWM system, robot, smoke purifier, protection room, etc.

Parameters

| Dimension | 5000(L)*4000(W)*6000(H)mm |

| Linear module positioning (Y) | 1000mm |

| Air volume of smoke purifier | 8000m³/h |

| Repeat Accuracy(XYZ) | ±0.03mm |

| Productivity/Efficiency | 14S/PC |