Auto Seat Frame Laser Welding

Application Description

Auto white body such as seat frame and others.

Standard

The surface of welding seam is smooth;

There is even pattern in the welding seam;

No air holes, spatter, burn-through, etc.

Advantage

Welding speed ≥70mm/s;

Flying welding with high efficiency, can jump in milliseconds between welding seam in the scanning range.

Technology

Difficulties

1. The laser welding needs smaller gap, and the product gap is difficult to ensure.

2. The robot needs to wait for manual uploading, so the productivity is no high.

3. The laser welding requires high level of safety, needs radiation protection, but the moving edge of the slide and turntable mechanism is difficult to protect.

Solution

Tips 1: Use intensive fixture design, add enough pressure blocks near the welding seam to eliminate the gap between products;

Tips 2: Use multiple welding position to improve overall productivity;

Tips 3: Use double shutter door to achieve double protection.

Features

- High welding quality;

- High reliability fixture clamping design to ensure the product gap;

- Optional welding quality monitoring system to monitor welding quality;

- Set 1-3 rotary table for different products welding;

- Multiple welding position for manual uploading and unloading, one robot for flying welding, which can reduce robot waiting time and improve efficiency.

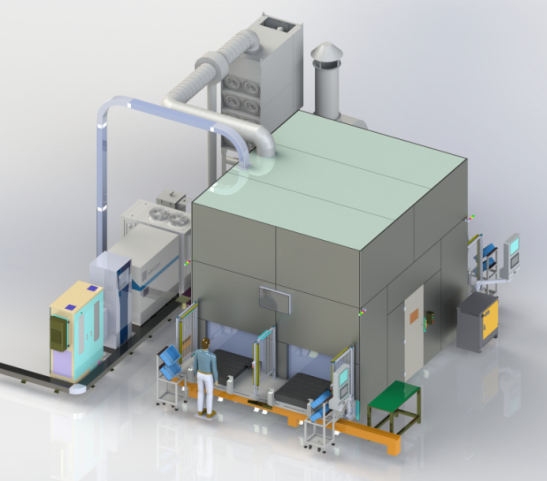

System Including

This auto seat frame laser welding system includes laser welding machine, laser head, chiller, smoke purifier, fixture, robot, electrical cabinet, shutter door, protective room, etc.

Parameters

| Dimension | 14(L)*4.5(W)*7(H)m |

| Welding speed | ≥70mm/s |

| Productivity/Efficiency | 35S/PC |