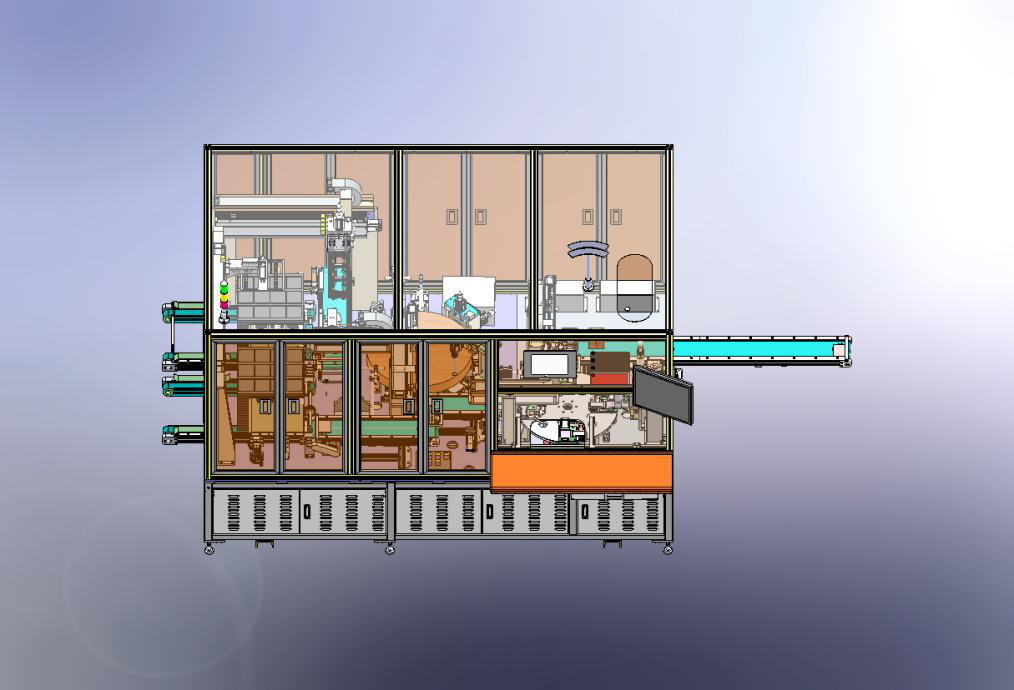

Battery Pole Ear Laser Welding

Application Description

Mobile Phone Battery Specification

Length: 40-120mm

Width: 30-80mm

Height: 2-5mm

Standard

The welding surface is smooth, and no obvious color change, no welding penetration.

Advantage

Superior rate ≥99 %

Productivity/Efficiency≥900 UPH

Welding speed 110~130mm/s

Technology

Difficulties

1. The pole ear is thin so that it is easy to deform and lead to poor welding.

2. The welding energy is unstable, and it is easy to produce welding penetration.

Solution

Tips 1: Integrate the laser welding machine with the position of pole ear shaping, cutting, dimension detection, and protection board welding avoid the risk of pole ear deformation.

Tips 2: Use energy negative feedback to ensure the stability of the energy.

Tips 3: Use the scanner to ensure the welding efficiency.

Features

- This battery pole ear laser welding system is used for scan code, internal resistance voltage test, pole ear shaping, pole ear cutting, protection plate welding, etc.;

- Flexible design is compatible with a wide range of product types;

- High degree of automation, the protection plate can be extended to automatically uploading;

- High welding speed, excellent effect and high superior rate;

- Key technology parameters (OCV test data, pole ear size, welding parameters, etc.) can be uploaded to the traceability system;

System Including

This battery pole ear laser welding system includes laser welding machine, worktable, chiller, etc.

Parameters

| Dimension | 3000(L)*1500(W)*1800(H)mm |

| Repeat Accuracy | ±0.03mm |

| Failure Rate | ≤2% |

| Productivity/Efficiency | 900 UPH |