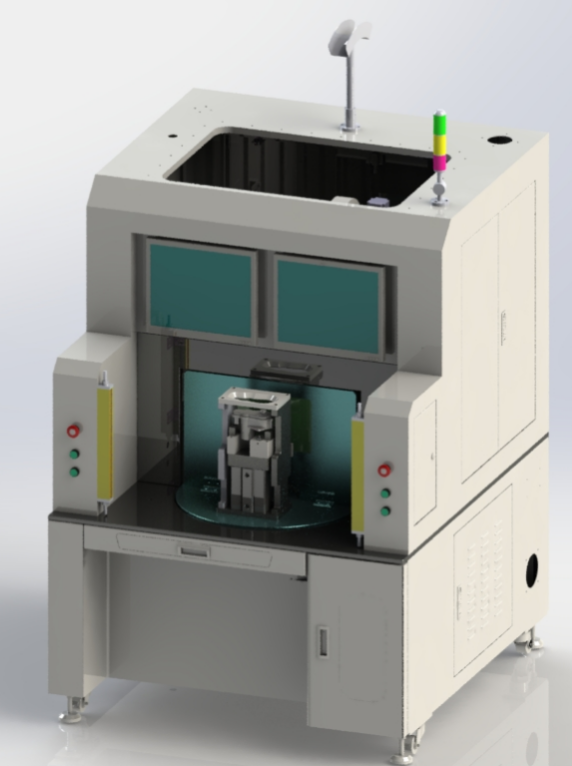

Electronic Brake Laser Welding

Application Description

Specification

All kinds of plastic products

Standard

Bursting pressure ≥6bar

Leakage pressure ≥ 4 bar

Destruction torque ≥ 4N·M

Advantage

Superior rate ≥99%

Productivity/efficiency≥5PPM

Technology

Difficulties

1. During plastic welding the unsynchronized collapse results in substandard air impermeability.

Solution

Tips 1: Design special fixture and use quasi-synchronous welding, so that the entire trajectory is uniformly heated and collapsed simultaneously.

Tips 2: Use collapse automatic control technology to ensure welding quality and product size.

Features

- Rotating double position design to improve efficiency;

- Increasing safety light curtains to improve safety;

- Use laser diode for welding, with small size, long life, good welding quality.

System Including

This connectThis electronic brake laser welding system includes laser welding machine, workstation, etc.

Parameters

| Dimension | 1200(L)*1300(W)*2050(H)mm |

| Repeat Accuracy(XYZ) | ±0.05mm |

| Failure Rate | ≤2% |