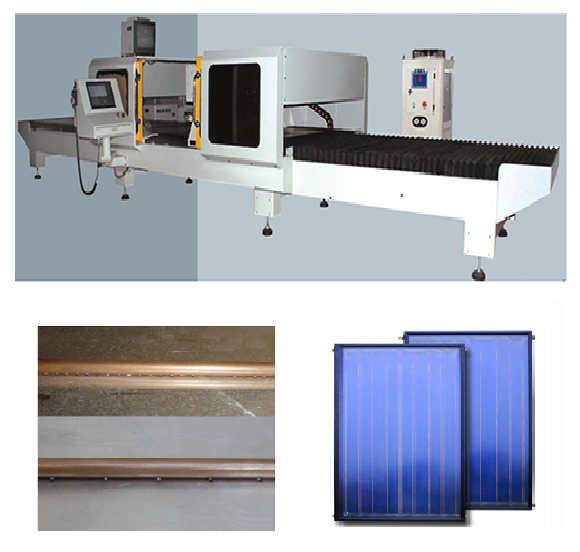

Flat plate solar energy collectors

1.1 Laser welding System Characteristics

- Two work stations of the system, uploading and downloading workpiece over one meanwhile welding over the other one.

- Output heads

- Welding speed: 4800mm/min=2400mm/min * 2 output laser beam

- Weld strength: Endure 1.3MPa Water pressure within copper tube for 5 minutes

- Auto correction on copper tube position range: 2mm

- Lifetime: more than 7 years if work 20 hours a day.

1.2 Weldment: Solar collector specification

PART1 | PART2 | |

Description | plate | Tube |

Material | Aluminum | Copper/Aluminum |

Thickness | 0.35-0.5mm | 0.45-0.7mm |

Max size | 3000mm*1000mm | 6-12.5mm |

1.3 Parameters of laser machine were used for the welded connection

Distance of 2 impulse welding point is adjustable from 2mm to 15mm Welding point diameter: 0.75-1.2mm

2. Configuration

Laser machine (Main) : GZ-300W | Fiber input and output system |

Laser output head | |

CCD display system | |

Laser machine(Accessory) | Chiller |

CNC Worktable | Worktable |

Control system |

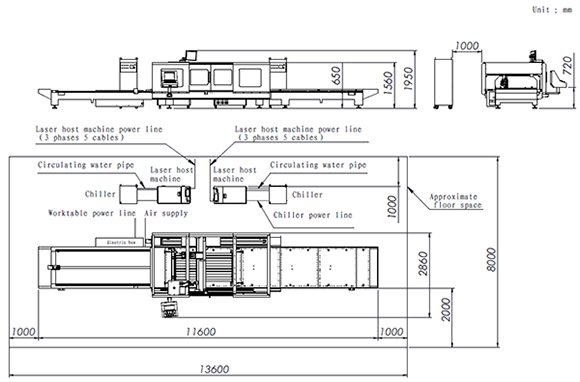

3. Layout:Floor space requires 13600mm*8000mm

4. The CNC worktable configuration

4.1 Enable enough length of solar collectors with big worktable

Self-developed models, the main rack made of high quality steel, computer gray appearance of the coating, the seal plate made of high quality Q235A steel plate, countertops flatness is± 0.06mm, Dimensions: (L * W * H): 11500 × 2800 × 1600 (mm)

4.2 Both cross tubes and straight tubes can be welded

Dual workstation, dual output head , 4D worktable, the output head can automatically rotate, suitable for solar collectors lateral, longitudinal welding, X, Y axis adopt servo drives, high precision ball screw and ball rail drive, X axis stroke 3000mm, Y axis stroke 1100mm,repeatly positioning accuracy±0.05mm; laser output head rotate automatically.

4.3 φ12 φ10 andφ8 tube clamping roller (specialized jig and fixture system) are available

Spacing distance of tubes turn left and right according to actual requirements, the laser head equipped with rollers (rollers run over tube during welding), ensure tube stick to plate tightly and welding well.

4.4 High stability of box structure and beams

Box structure base and beams using precision casting Aluminum alloy work platform, with annealing aging and vibration aging etc. eliminating stress process test.

4.5 Industrial PC control

Array point welding and straight line trajectory welding, welding trajectory are decided by CNC programming or teaching programming, welding process automation, welding procedures can be modified, you can set the operation and modify permissions;

4.6 Adjustable focal length

Laser output head can go up and down to adjust focal length, standard configuration 17-inch monitor.