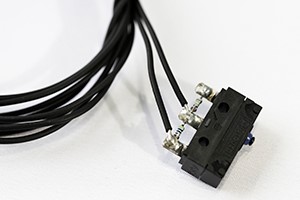

Micro Switch Laser Welding

Application Description

Specification

Various small electronic components

Standard

Tin through rate ≥ 75%

Advantage

Superior rate ≥ 99%

Productivity/efficiency ≤ 1S/PC

Technology

Difficulties

1. The substandard tin through rate;

2. The laser reflection and burns the components;

3. High temperatures cause the PVB board burns.

Solution

Tips 1: Use special technology to improve the tin through rate.

Tips 2: Use special spot to reduce reflection.

Tips 3: Add the temperature control system to control temperature.

Features

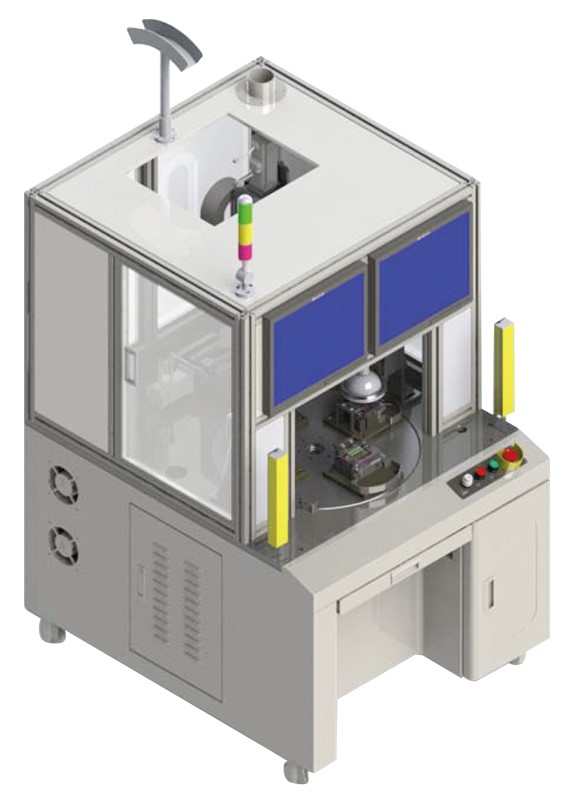

1. Rotary double position design to improve efficiency;

2.Increasing safety light curtains to improve safety;

3.Test system of before welding and after welding to improve product superior rate;

4.Temperature control system to prevent board burning.

System Including

This micro switch laser welding system includes laser welding machine, workstation, etc.

Parameters

| Dimension | 900(L)*1100(W)*1555(H)mm |

| Repeat Accuracy(XYZ) | ±0.05mm |

| Failure Rate | ≤2% |