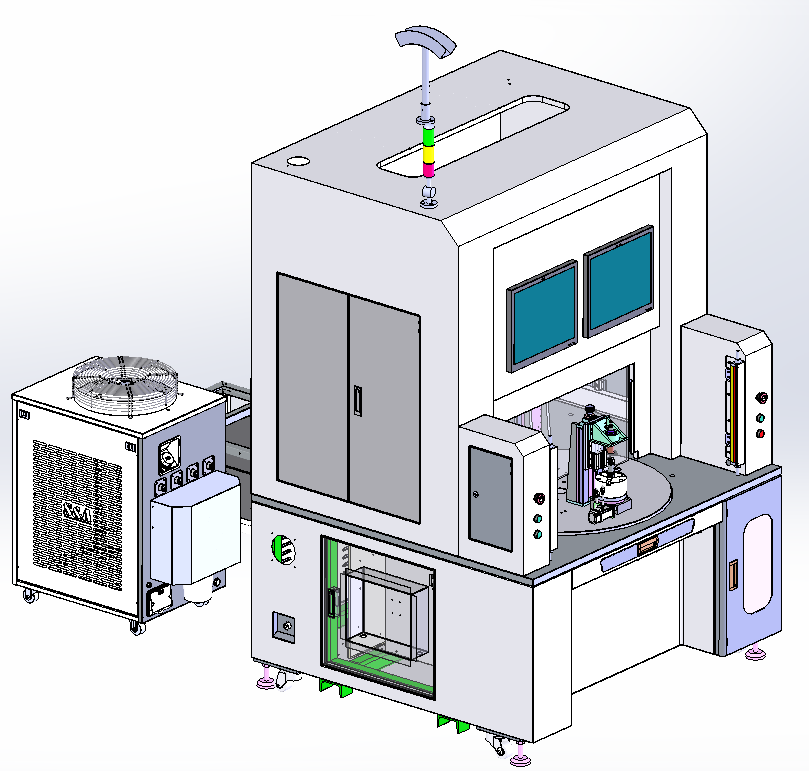

Sensor Laser Welding System

Application Description

Sensor Specification

Cylindrical shape

Standard

Welding surface is smooth and clean (Ra0.32).

Pressure test (3Mpa).

Advantage

Superior rate: ≥99%

Welding speed: 40mm/s

Technology

Difficulties

1.Diaphragm welding deformation, fixture concentricity control, diaphragm welding become yellow.

Solution

Tips 1: Fixture coaxial gas blowing, excellent coaxiality of the fixture ensures welding effect

Features

1. The motion axis is driven by a servo motor and uses precision ball screws and linear guides as transmission elements. The precision is high and the speed is fast. The max dry running speed is 300mm/s. The positioning accuracy is ±0.03mm/min, repeat accuracy is ±0.02mm. The rotate is driven by servo and positioning accuracy is ±0.02mm/min.

2. Fiber laser welding machine, with high electro-optical conversion efficiency, high welding speed, large depth-to-width ratio, energy concentration, and small heat-affected zone, small volume, no consumables, and no maintenance.

3. Laser head with collimation system to facilitate the connection with the fiber laser welding machine; drawer-type protection lens can quickly replace and maintain the optical elements; air knife and coaxial gas protection function; CCD monitoring system the welding process can be monitored in real time.

System Including

This sensor laser welding (double position) system includes laser welding machine, double position worktable, chiller, etc.

Parameters

| Laser welding machine | GZ-500CW |

| Laser head | With CCD |

| Chiller | CW-6100AT |