Vacuum Cup Laser Welding

Application Description

Vacuum Cup Specification

Diameter: 175mm

Height: 45mm

Standard

Welding surface smooth.

Pressure test (3Mpa).

Advantage

Welding speed: 20-30mm/s

Technology

Difficulties

1.In the sheet metal industry, weld seam position deviations and plate deformation results in big weld gaps.

Solution

Tip 1. Use mature fixture to compress weld gap to meet welding requirements.

Feature

1. Fixture compatibility design to meet the needs of product change. With real-time tracking device can guarantees the follow-up of focus and tracking welding position in real time.

2. Fiber laser welding machine, with high electro-optical conversion efficiency, high welding speed, large depth-to-width ratio, energy concentration, and small heat-affected zone, small volume, no consumables, and no maintenance.

3. Laser head with collimation system to facilitate the connection with the fiber laser welding machine; drawer-type protection lens can quickly replace and maintain the optical elements; air knife and coaxial gas protection function; CCD monitoring system the welding process can be monitored in real time.

System Including

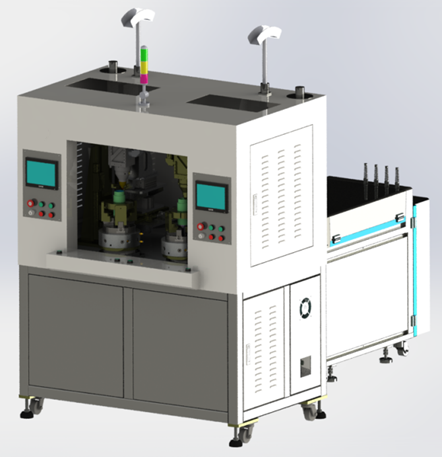

This vacuum cup laser welding system includes laser welding machine, chiller, fixture, workstation, etc.

Parameters

| Dimension | 1400(L)*860(W)*2000(H)mm |

| Welding speed | 20-30mm/s |

| Repeat Accuracy | ±0.03mm |