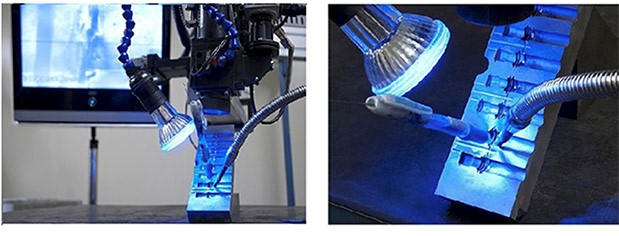

Mold Repair Welding Machine

Product Introduction

- Flexible structure can match more different shape and size.

- The body CNC can move manually Y 700mm

- Laser head can move with the servo motor X*Y*Z traverse 150*150*600mm by joystick

- Laser head can move with shaft 35 ° in all direction by hand

Technical Parameters

| Model No. | GZ-MR-7 |

| Peak Power | 7KW |

| Max pulse power | 80J |

| Pulse frequency | 1—-20Hz |

| Machine power consumption | 12kW |

| X-axis stroke | 150mm |

| Y-axis stroke | 150mm |

| Z-axis stroke | 600mm |

| Aiming positioning | Red light(CCD ) |

| Power supply | 380V 3Phases 50/60Hz |

| Machine size(mm) | 630(W)* 1030(D)* 880(H) |

| Cooling type | Water chiller(2P) |

Mold Repair Welding Machine Advantages

- No cracks, sand holes, scars, deformation, and oxidation

- Laser welding point diameter of only 0.2mm ~ 2.0mm

- Small range of heating without stomata

- Can repair cracks, corners, mold edges and worn edges

- Make welding parts up to HRC 60°hardness

Mold Repair Welding Machine Features

- Easy operating 1064nm pulse YAG laser to match different material welding and repairing.

- Intelligent laser parameter setting with panel for different material mold repair with/ without different material wire.

- Can be suitable for welding a variety of mold materials: S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2082 and other countries die steel.

- Laser spot welding with joystick control moving and foot pedal control laser shot.

- CCD magnify 30 times of the position to be welded and repaired.

- Comparing with microscope, CCD is more ergonomic and cost-effective.

Mold Repair Welding Machine Application

- Mold repair in digital products, mobile phones, autos etc.

- Molding industry, precision casting industry etc.

Mold Repair Welding Machine Effect

Through the mold repairing, you can re-use the original mold, which can save the production costs and improve work efficiency. It can be used to modify the design or size of the mold, reducing the product development cycle.

- The welding depth is large. The welding effect is strong. The melting is sufficient without repair traces

- Small heat range will not lead to precision mold deformation

- Wide processing materials

- It can repair the mold sand holes, cracks, collapse angle, mold edge, etc.

- The weld bead can be grinding and processed into smooth surface

- Without depression at the mold repair position of the molten pool melting part of the junction