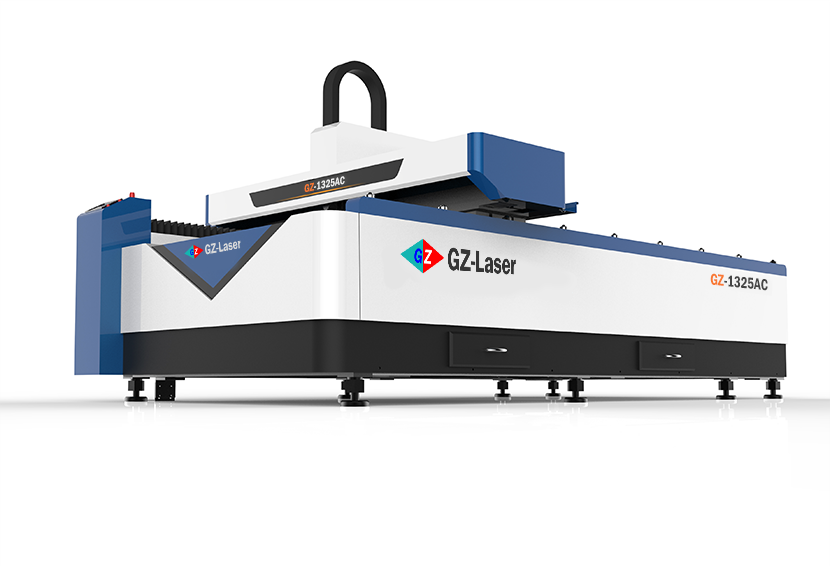

GZ-1325AC Combined Fiber and CO2 Laser Cutting Machine

Product Introduction

The model GZ-1325AC combines both Fiber laser cutting system and CO2 laser cutting system, which is a most valuable laser cutting machine cutting both metal professionally and at the same time work with non-metal material, using the self-developed machine gantry structure, the whole machine uses high strength seamless steel for a better rigidity, high temperature annealing machine, and the rack for many years usage without deformation, accompanied by fiber laser generator and CO2 150w top great laser tube. High quality optic devices come with excellent beam to make the cutting lines more sophisticated and more efficient. The railways and ball screw is imported high precision brand, also additionally equipped with a dust removal device, drag feeding device, high temperature alarm and industrial cooling devices.

Main Configuration

Transmission and Precision

- High precision TBI ball screw transmission

- Delta AC servo motor and drive from Taiwan

- High precision HIWIN guide rail from Taiwan

- Untouched following control system

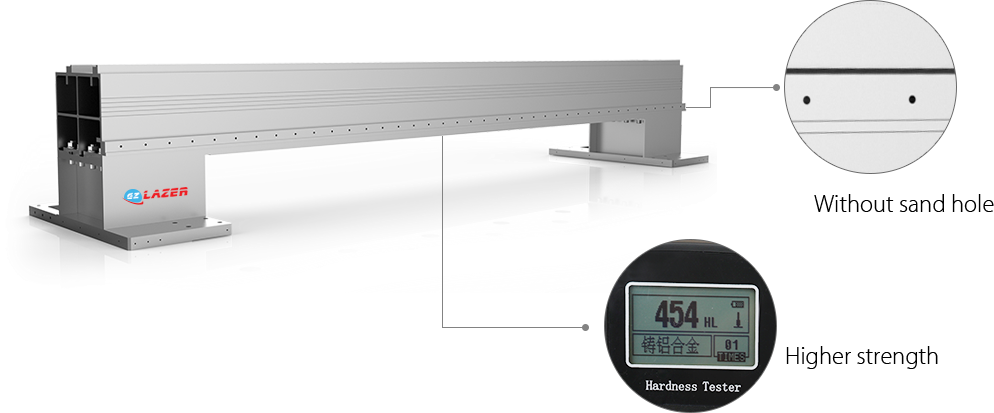

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Low Power Consumption

Technical Parameters

| Model Type | GZ-1325AC |

| Laser Generator | 1000W~2000W Raycus/IPG fiber laser & CO2 150w glass tube |

| Cutting head | Professional fiber cutting head & CO2 laser cutting head |

| Control system | Both fiber and CO2 cutting operation |

| Working area | 1250*2500mm |

| Max. cutting speed | 0-20m/min(Depending on the material and thickness) |

| Cutting thickness | 8mm for metal and 25mm for acrylic |

| Repeat accuracy | ±0.03mm |

| X-axis travel | 1250mm |

| Y-axis travel | 2500mm |

| Z-axis travel | 100mm |

| Power supply | 220V/50Hz~60Hz |

| Net weight | 1400KGs |

Fiber Laser Cutting Machine Features

- Moved crossbeam with imported high precision ball screw and rail guide transmission makes the stable driving and high precision work.

- Machine frame, crossbeam and worktable adopt integral welding, in accordance with the standard large machine, to stress annealing after rough machining, and then vibration aging treatment, can completely eliminate the welding stress and processing. Can also keep high strength, high precision, and also keep many years of normal use without deformation.

- X and Y axis are equipped with Delta servo motor, high precision, high speed, large torque, and large inertia for a steady and durable work.

- Use MPC6595 based on Windows operating system can perfect match the Laser cut 6.1, collect the function of read file, simple design, output, and processing control, a set of software which can complete the layout to the machining process, integrated with laser cutting control special function module which is powerful with a good man-machine interface and easy to operate.

Fiber Laser Cutting Machine Application

- Applicable to fast cutting on plate or tube in metal, mainly for cutting on SS, carbon steel, Manganese steel, galvanized plate, alloy plate, rare metal.

- Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.