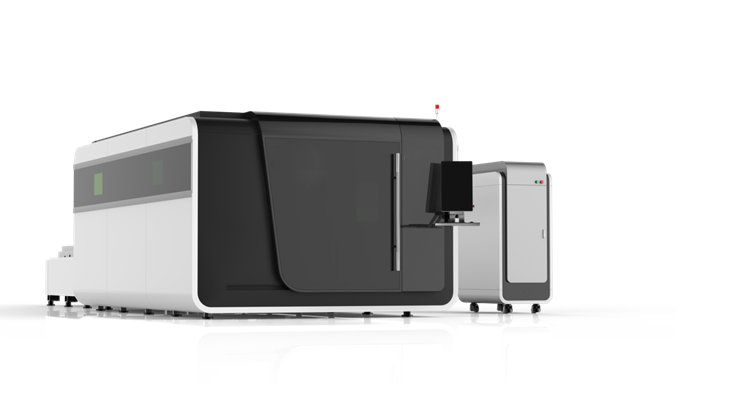

GZ1530CG Fiber laser cutting machine with housing

Product Introduction

The model GZ1530CG fiber laser cutting machine consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

It has been widely used in manufacture billboard, sheet metal structure, high-low voltage electric cabinet, textile machinery, kitchenware, metal artwork, etc.; processing material like Stainless steel, carbon steel, Silicon steel, alloy steel, spring steel, copper, aluminum sheet, Zinc alloyed sheet, etc.

Main Configuration

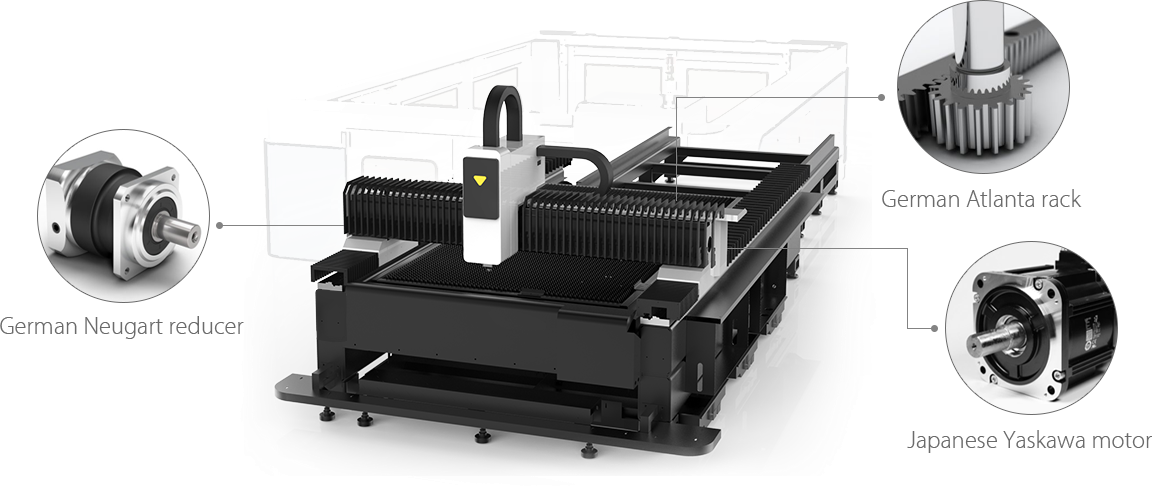

Transmission and Precision

- Atlantad double gear and rack transmission from Germany

- X,Y axis are equipped with Yaskawa double AC servo motor and drive from Japan

- German Neugart reducer or French MOTOREDCER

- High precision HIWIN guide rail from Taiwan

- High Precision TBI ball screw transmission for Z axis from Taiwan

- Schneider Electric Relays

- Professional Cypcut control system

Auto Focus Cutting Head

- Auto Focusing: The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

- Bigger Adjustment Range: Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

- Long Life Span: Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

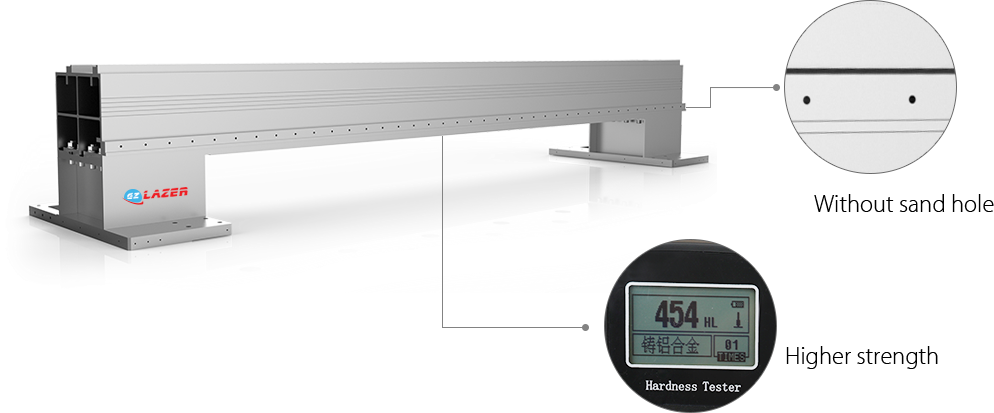

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

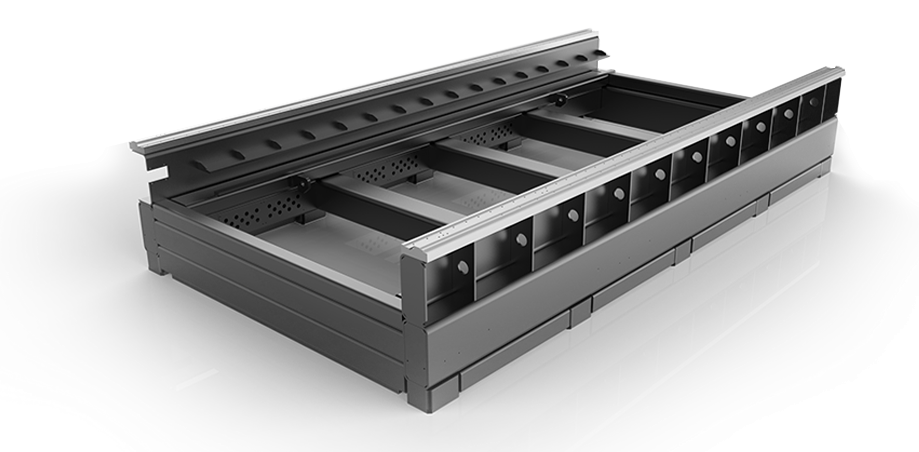

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, and it also increases the resistance and stability of the guide rail to effectively avoid the deformation of the bed.

The Segmented Rectangular Tube Welded Bed

- High strength, stability, tensile strength, ensuring 20 years of use without distortion

- Thickness of rectangular pipe wall is 10mm and weights 4500 kg

Independent Control Cabinet

- Dust-proof: All electrical components and laser source are built-into the independent control cabinet with a dust -proof design to prolong the lifespan of the electrical components.

- Automatic Thermostat: The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

IPAD Designed Screen

IPAD designed screen, has a vertical screen display, different from the traditional horizontal screen display, which is with good response speed, higher contrast, wider view, low power consumption as well as high resolution. In addition, it possesses high brightness levels and lower reflectivity as well as solid glass panel sturdiness and durability.

Technical Parameters

| Laser Generator | Imported/Chinese fiber laser generator |

| Laser power | 2000W/3000W/4000W/6000W/8000W/10000W/12000W/15000W |

| Working area | 1500*3000mm/1500*4000mm/2000*4000mm/2000*6000mm |

| Max. speed | 0-20m/min(Depending on the material and thickness) |

| Repeat positioning accuracy | ±0.02mm |

| X-axis travel | 1525mm(take 1500mm for example) |

| Y-axis travel | 3025mm(take 3000mm for example) |

| Z-axis travel | 100mm |

| Acceleration | 1.5G |

| Transmission | Germany high precision gear with double driving rack |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | Above 7000KGs |

Fiber Laser Cutting Machine Features

- Moved crossbeam with imported high precision racks and linear guide rail, transmission stable, working with high precision.

- Machine tool, crossbeam and worktable adopt integral welding structure, machine tool, crossbeam and worktable adopt integral welding structure, in accordance with the standard large machine, to stress annealing after precision finishing and then for vibration aging treatment, it can completely eliminate the welding stress and processing stress, keep high-strength, high precision, and also keep the 20 years of normal use without deformation.

- X, Y and Z axis use imported Japan servo motor, high precision, high speed, large torque and large inertia, performance is stable and durable, ensure the high speed operation of the whole machine.

- Based on Windows operating system, use professional Cypcut numerical control system for fiber laser cutting machine, integrated with laser cutting control special function module which is powerful with a good man-machine interface and easy to operate.

- Laser-produced without gas, it could use air to cut sheet metal.

Fiber Laser Cutting Machine Application

- Applicable to fast cutting on plate or tube in metal, mainly for cutting on SS, carbon steel, Manganese steel, galvanized plate, alloy plate, rare metal.

- Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.