GZ60T1 Tube Fiber laser cutting machine

Product Introduction

The model GZ60T1 fiber laser cutting machine is professionally designed for both round and square tube cutting. It consists of machine tool, motion parts, electrical equipment control parts, and other assist parts. It has been widely used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube. It can achieve the tubes/pipes multi-angle precision processing to fulfil the requirements.

Main Configuration

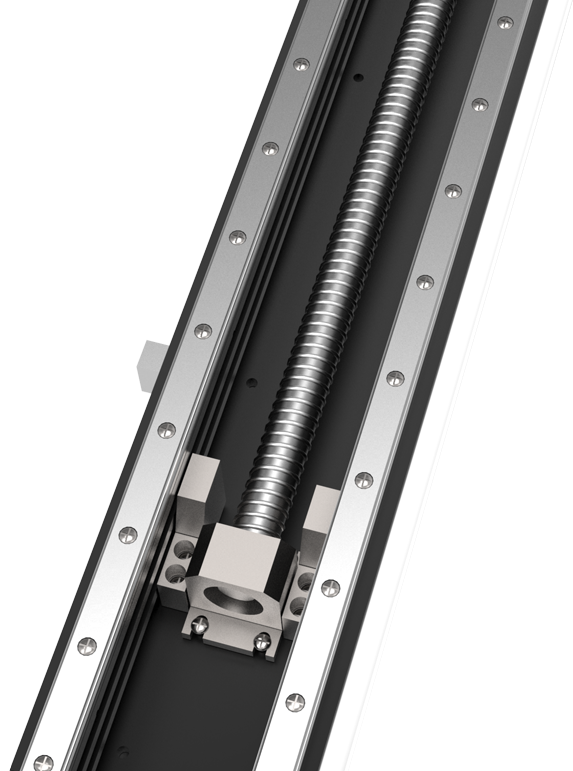

Transmission and Precision

- High precision TBI grinding ball screw transmission, double drive for Y axis

- Panasonic AC servo motor and drive from Japan

- High precision HIWIN guide rail from Taiwan

- High Precision TBI grinding ball screw transmission for X and Z axis

- Schneider Electric Relays

- APEX gear rack from Taiwan

- Professional Cypcut control system

Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

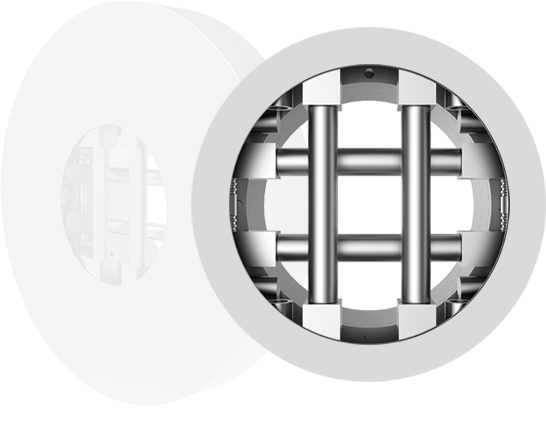

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Easy to Operate

It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation.

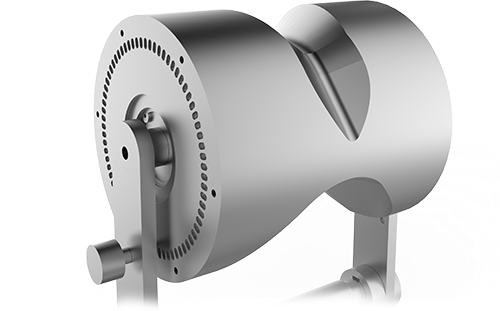

Auto Focus Cutting Head

- Auto Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

- Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of the plates.

- Long Life Span

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life span of the cutting head.

Technical Parameters

| Model Type | GZ60T1-1000W / 1500W / 2000W |

| Laser Generator | Raycus/IPG fiber laser generator |

| Laser power | 1000W/1500W/2000W/3000w/4000W |

| Repeat positioning accuracy | ±0.02mm |

| Tube device | 6m, tube diameter 20~220mm |

| Transmission | Taiwan TBI grinding screw drive |

| Power supply | 380V/50Hz~60Hz |

| Gross weight | 4500KGs |

Fiber Laser Cutting Machine Features

- It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation.

- It employs intelligent tube support design, which can solve the deformation problems in the processing of long tube cutting.

- It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-220mm.

- X, Y, and Z axis is equipped with Taiwan TBI grinding screw drive.

- X, Y and Z axis use imported Japan servo motor, high precision, high speed, large torque and large inertia, performance is stable and durable, ensure the high speed operation of the whole machine.

- Based on Windows operating system, use professional Cypcut numerical control system for fiber laser cutting machine, integrated with laser cutting control special function module which is powerful with a good man-machine interface and easy to operate.

- Laser-produced without gas, it could use air to cut sheet metal.

Fiber Laser Cutting Machine Application

- Applicable to fast cutting for metal tubes and pipes, mainly for cutting on SS, carbon steel, Manganese steel, galvanized plate, alloy plate, rare metal.

- Widely used in oil industry, kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.